GEMTECH POWER CONTROL PVT. LTD.

A professional organization spread over an area of more than 40,000sq.ft. engaged in manufacturing of Electrical and Automation Based control panels, Bus Ducts, Rising Mains, Cable Trays and Raceways required for Power plants, Engineering and Process Industries, Hospitals, Corporate and Commercial Sites. The company also trades, contracts and deals in H.T.. Panels, H.T.. Transformers, C.S.S. and executes turnkey projects (electrical).

We got our panels in time as promised as well as the installation process was so quick and smooth that we didn’t even realize how quickly it happened. We always get our electrical system upgraded from Gemtech Power Control whenever we expand because they are honestly the best in the business.

Sarabjeet Singh

Director

Whirlpool of India Limited, Faridabad

Gemtech Power Control gave us the best experience so far. They were strictly on schedule and delivered the quality that was promised. The support staff was also very helpful and did a very good job.

M.L. Sharma

Managing Director

Glen Appliances, Faridabad)

PRODUCTS

Main LT Panel receives the main power supply either from Generator or Transformer and distributes the same to various distribution boards and other devices depending upon the requirements of the system. With the help of protective switch gears, they are used for controlling and monitoring the mains supply from a centralized location

- Single/Multiple Incomers & Bus Couplers

- Mechanical/Electrical Interlocking

- Top/Middle/Horizontal Bus Bar Chambers

- Aluminum/Copper Bus Bars

- Top/Bottom/Front/Rear Cable Terminations

- Combination of APFC with PCC

- Facility of DG Incomer with AMF

(also with PLC System)

Successfully Installed

Panels with Main Incomer of rating up to 5000A.

DG synchronization panels control functions like auto starting of DGs, auto load sharing of multiple DGs and load managing. These operations are done by PLC or any other intelligent microprocessor based relays. These are instrumentation based panels; auto synchronization and load sharing functions are done as per specific requirements of the customers.

Synced 7 Nos. 1250KVA DGs successfully at

Whirlpool of India Limited, Faridabad

APFC (capacitor) Panels which are extensively used in various industries to save energy and reduce power bills. These Automatic Power Factor Control Panels (APFC) are designed with Microprocessor based relay for controlling Power Factor within required values. We make these panels fully ventilated, and use easy maintenance, easily removable capacitors. These also have provision of detuned reactors for reliable operation in presence of harmonics.

also with

Thyrister Switching

2000+Successful Installations

MCC stands for Motor Control Center. It consists of feeders for motors and blowers. Feeders are designed according to the motor rating. The signal is given by the control panel. Indicators for the motor operation also will be present in control panel. A motor control center (MCC) is an assembly of one or more enclosed sections having a common power bus and principally containing motor control units. Motor control centers are in modern practice a factory assembly of several motor starters. A motor control center can include variable frequency drives, programmable controllers, and metering and may also be the electrical service entrance for the building.

also with PLC/SCADA system

1500+ Successful Installations

PLC based Process Automation Panels can be programmed with PLC as per needs of the customer to better control and process industry.

For saving electric energy consumption, it is necessary to fully monitor various parameters and according controlling various factors. We manufacture PLC based Electric Data Monitoring Panels which monitor closely, various electric parameters in industries and help us to find the problem area to reduce electric energy consumption.

Successfully Implemented PLC systems

for Food Industries, Dairy Plants etc.

We offer Small & Large Power Distribution Panels to receive inputs, trigger outputs, and monitor systems and instrumentation. The distribution panel divides an electrical power feed into subsidiary circuits and simultaneously provides a protective fuse or circuit breaker for each circuit. The board has a common enclosure and we fabricate distribution panels of different capacities for use in a variety of industrial, manufacturing and process control applications, across diverse industries.

AC drive panels are widely used as speed controllers of alternate current induction motor. Used across various industries, AC drives are used to control the speed of motor by controlling frequency of supply. In AC drives, frequency and voltage are changed in same proportion for smooth performance of ac motor.

Variable frequency drive control panel (also named VFD panel, AC drive electrical control panel) is consisted of inner VFD inside the cabinet with external control, protect, display and other electrical, it’s an frequency conversion device to control three phase AC motor (including fans and pumps) in variable speed to save energy.

In electric power distribution, a bus duct (also called busway), is a sheet metal duct containing either copper or aluminium busbars for the purpose of conducting a substantial current of electricity. It is an alternative means of conducting electricity to power cables or cable bus.

To keep electric cables neat and clean as well as easy to maintain at various industries, we manufacture GI perforated pre and post galvanized, MS powder-coated perforated and Ladder cable trays and raceways as per customers’ needs.

- Complete Electrical and turnkey solutions consisting electrical design, fabrication, supply and installations.

- Complete HT solutions (indoor/outdoor), power transformers, HT, switchgears, HT cabeling and

power generators. - Supply and laying of HT/LT cables

- Supply and installation of earthing and earthing strips.

- Supply and installation of lighting fixtures (turn-key projects only)

Basic automation features

We provide panels with AMF, APFC, Auto Load Management, DG Synchronization, Process Industry Automation and other basic automatic features.

On-site management

Basic Onsite management of industries like Using Mimic Panels for Process Industries, using SCADA for Data Recording and analyzing and maintaining Log Books for APFC Panels are some of the things.

Online support

Options like Troubleshooting of faults by remotely accessing PLC Panels are also available.

Latest trends

Our Panels are Compatible with the Latest Trends like BMS, Solar System, Fire Suppression System and more

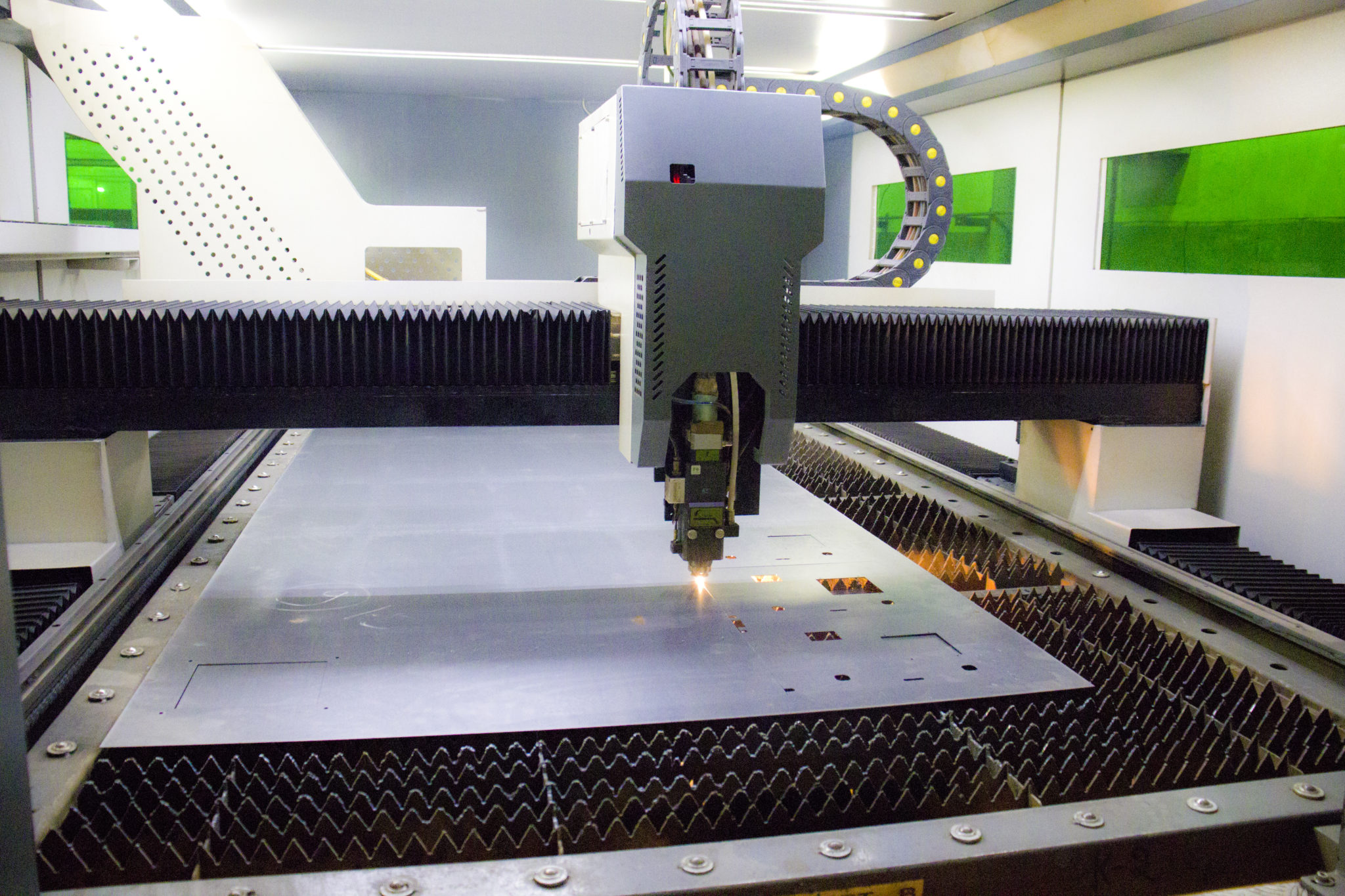

Factory Tour

Fabrication

Panels and cable trays of all dimensions, Forms and thicknesses are cut using Fibre Laser Machine and fabricated at the factory unit itself using the latest machinery and techniques.

Powder coating

All panels undergo pre-treatment cleaning processes

of de-rusting & de-greasing and then Powder Coated as per the desired color

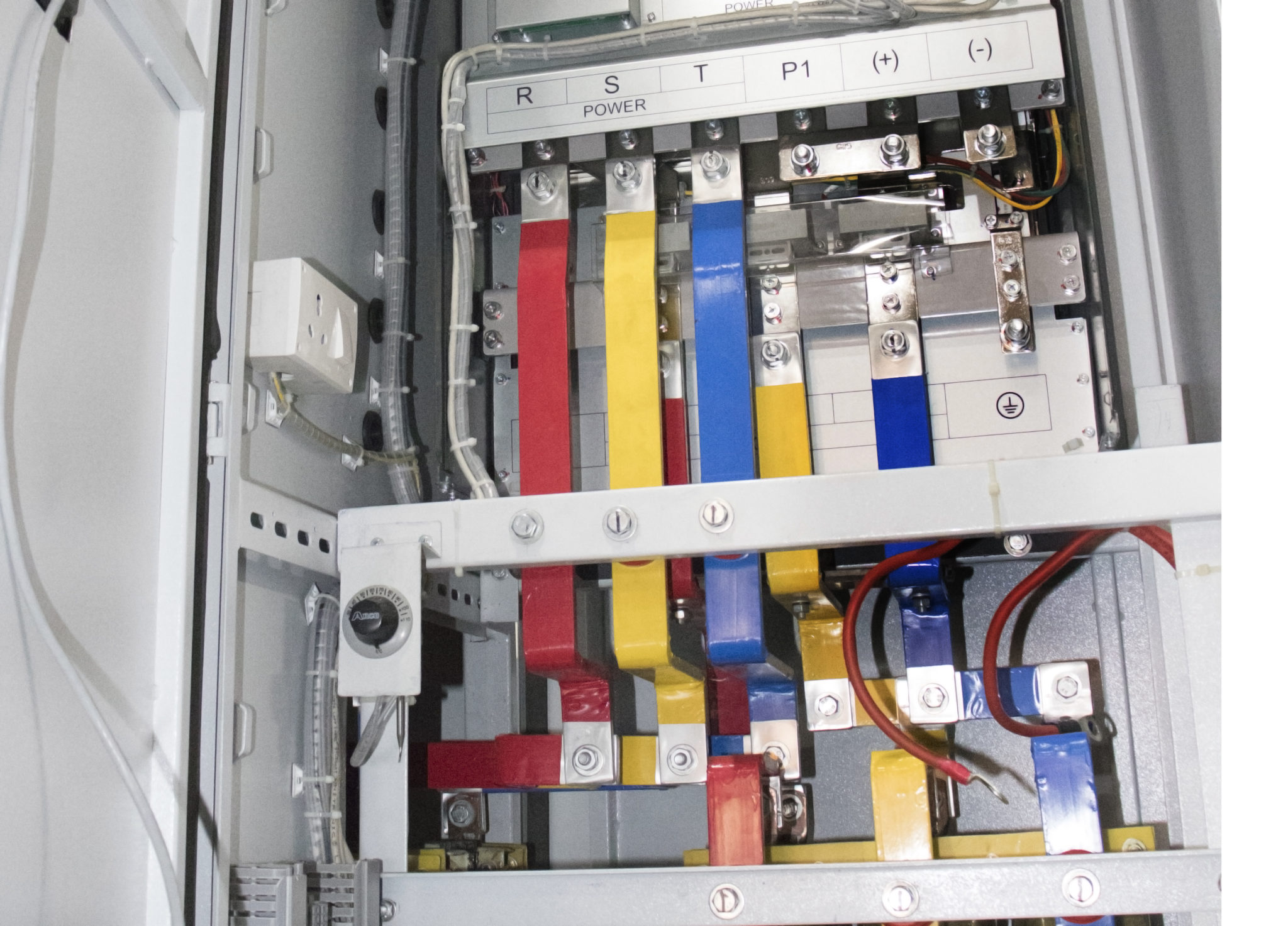

Assembly

All panel assemblies are

done in-house i.e.,Stress-free Bus-bar arrangement, optimized mounting of

equipment and wiring in order

to exercise all quality checks

and inspections.

Certified to

ISO 9001:2015

QMS

Tested by CPRI for

Short Circuit

Strength

Tested by CPRI for Temperature Rise

NSIC

Resistered

MSME

Registered

Manufacture Panels upto IP65

Major Clients